What is productivity?

We believe that productivity includes every aspect of operational excellence, from the generation of an idea for a product through its manufacture, sale, maintenance, and, potentially, dismantling and recycling once it becomes obsolete.

But the problem now, as a generation ago, is that organizations too often overinvest in technology while underinvesting in the human capabilities needed to make it useful. How companies transform themselves depends, to a great extent, on the capabilities they need most. We see four primary structures, which collectively become Operations 4.0:

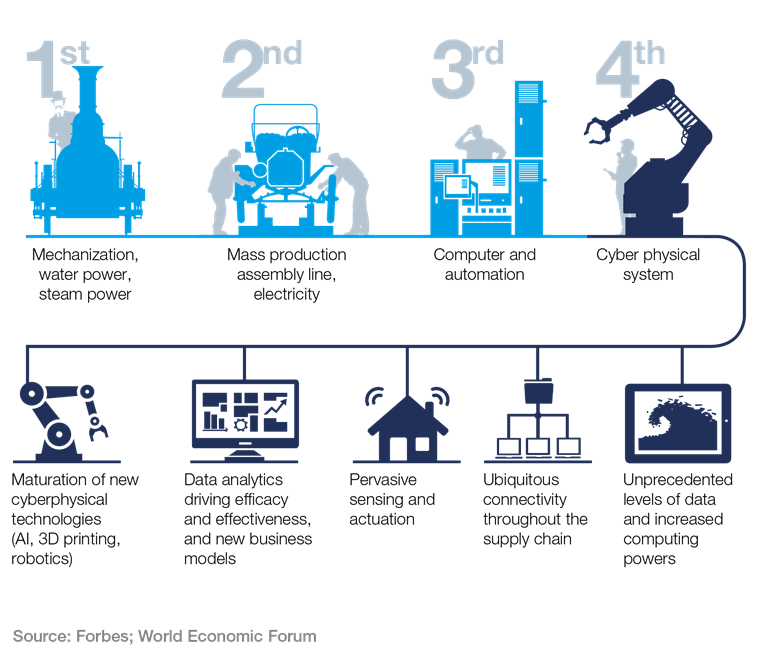

In the fourth industrial revoluton, digital anaylitcs enables a new level of operational productivity

Product-driven transformation: From cost to design to analytics-to-value

The next level of product transformation not only combines the latest design thinking with multiple sources of data but also exploits sophisticated advanced-analytics methodologies to generate insights about potential cost and value improvements. For example, computer-aided design tools linked to vast pools of procurement data, social-media activity, and cost and complexity benchmarks can allow a company to quickly identify designs that maximize profitability while minimizing wasted time and effort.

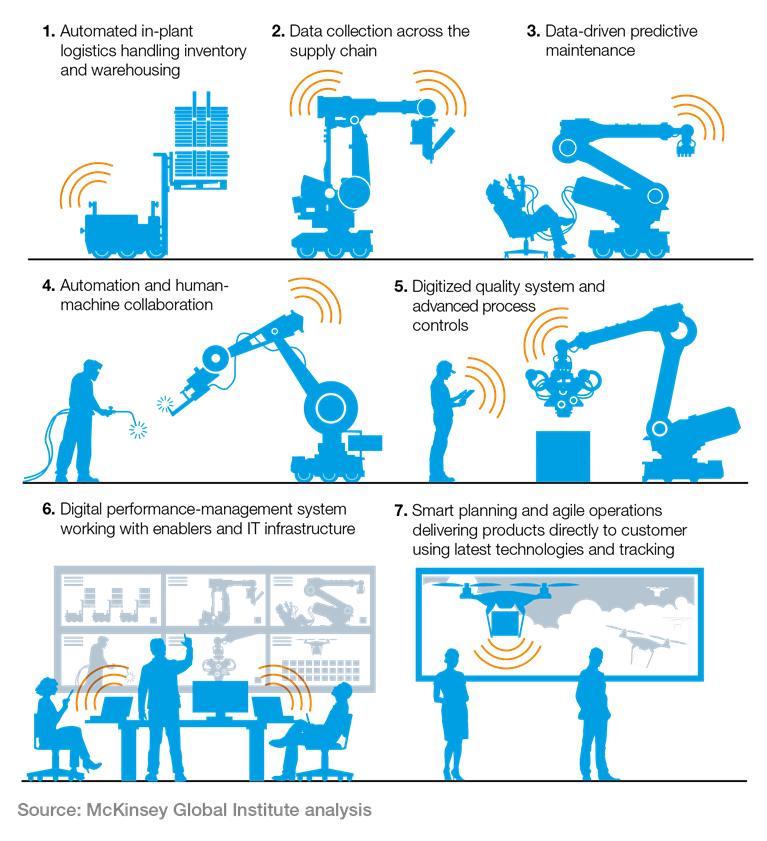

The factory of the future combines technologies that are available today

Combining people, novel digital technologies, and advanced analytics can yield a new breakthrough in productivity if companies learn to weave them all together. That’s the power of Operations 4.0 for organizations willing to commit themselves to it.